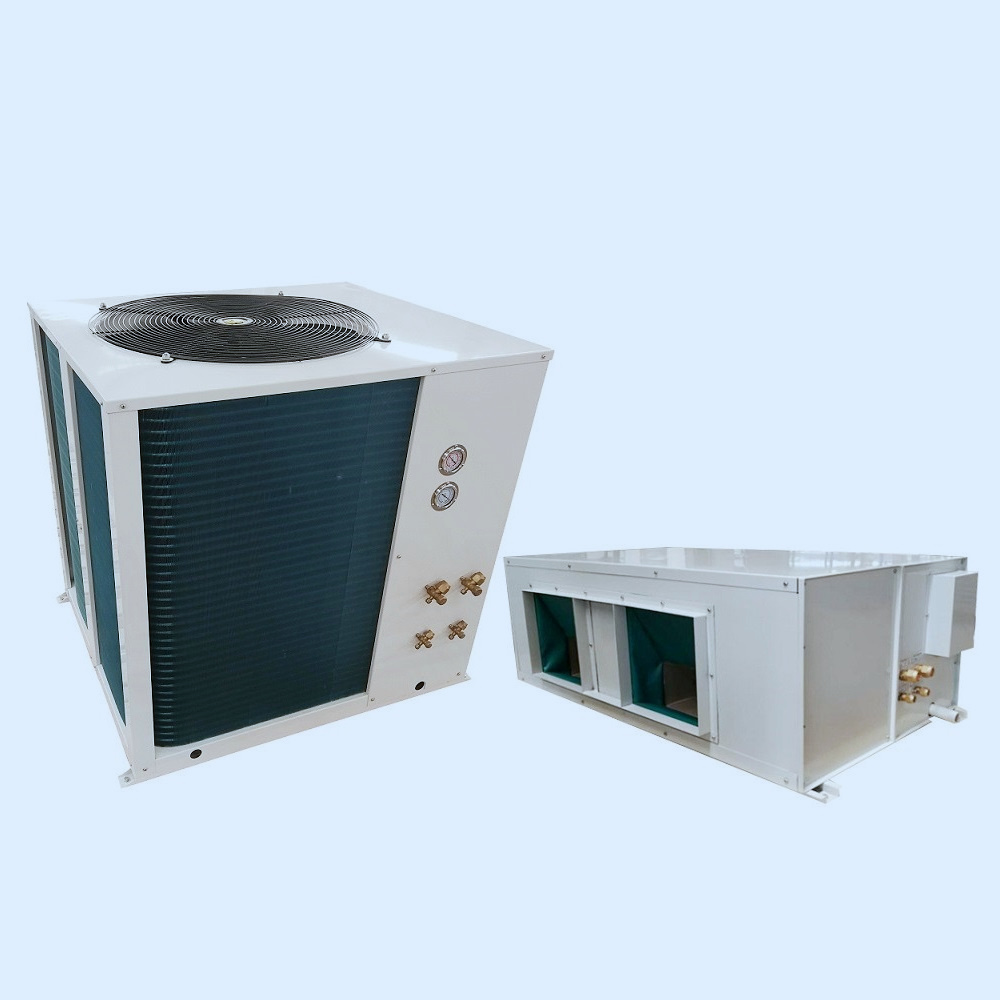

Split Commercial Unit

Features

Convenient for unit selection

Wide application

Sendo split type air conditioners are designed and manufactured to meet the requirements of the home, office, hotel and others public occasion use. Cooling capacity is from 6Ton to 52Ton (19.5kW to 180.8kW).

Colour selection

The frame & panel can be ordered in either white or dark grey colors.

1. Scroll compressor, Copeland or Panasonic brand, more reliable.

2. Coils are manufactured from seamless copper tubes mechanically expanded into hydrophilic aluminum fins.

3. Multiple protection, Schneider Electric brand, safe and reliable.

4. Fully exposed refrigerant connections and a single control panel cover make servicing easy.

5. Split units (50Hz and 60Hz) are 100% tested at the factory.

Type selection

• Conventional split series

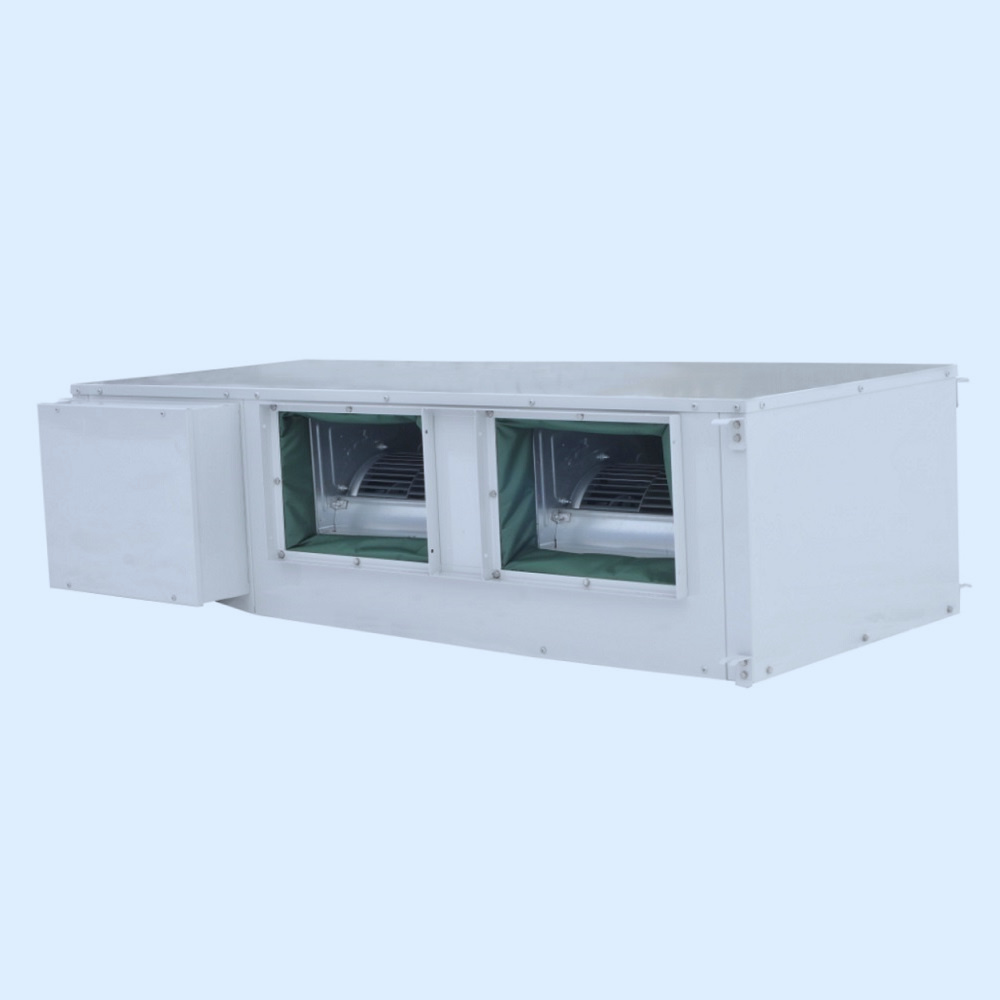

Available in 3 installation types for Indoor Unit: ceiling concealed ducted, floor standing ducted and floor standing free blow.

• DX air handling unit (AHU) series

Additional function section for Indoor Unit is optional, such as Mixing section, Filter section, Electrical Heater section and Hot Water Coil section etc.

Panels selection

Panels for Indoor Unit can be constructed of galvanized steel coated or double-skin with injection of high density polyurethane.

Reliability

• Standard cabinets are constructed from high grade galvanized steel with polyester powder coated, pre-painted exterior cabinet panels pass Salt Spray Test for durability.

• Split units are equipped with hermetic scroll type compressor, the voltage utilization range is ±10% of unit nameplate voltage. An electric heater around the compressor crankcase to ensure stability starting. Famous brand compressor: Copeland and Panasonic, more reliable.

• Coils are manufactured from seamless copper tubes mechanically expanded into hydrophilic aluminum fins, they are tested at the factory to avoid weld leakage.

• Outdoor fan is multi-blade vane-axial type, made of aluminum alloy for quiet operation & durability. It is directly driven by waterproof motor to ensure reliable continuous operations.

• Indoor fan is centrifugal type. The fan is directly driven (Model 20~100) & belt driven (Model 120~180) by waterproof motor. The fan and motor assembly is tested and dynamic balance is implemented in the factory.

• Multi-protection design, electric panel consists of breakers and contactors for compressors & fan motors, phase sequence relay and other necessary protection devices to ensure units operate normally and reliably. All electric parts are Schneider Electric brand.

• Sendo split units are tested at the factory to make sure no welding leakage and provide reliable start up at job site.

Quiet operation

• Compressors and low noise Supply Fan are mounted on rubber vibration dampers to reduce noise.

• Wave type acoustic Insulation for compressor section, the inside of indoor unit panels will be covered with 10mm insulation to prevent heat and noise coming out.

Easy installation and maintenance

• The units are completely assembled, internally wired, charged outdoor unit with refrigerant at the factory. The site work only needs to connect refrigerant pipes and communication wires between outdoor & indoor unit.

• Quick release fasteners provide convenient access to system components for maintenance.

Control system

SYSLAB wired controller is supplied with unit controls as standard. The precision control makes all heating, cooling, or ventilating decisions in response to electronic signals from sensors measuring indoor and outdoor temperatures. Precision temperature & humidity control is optional solution.

Assembly Line