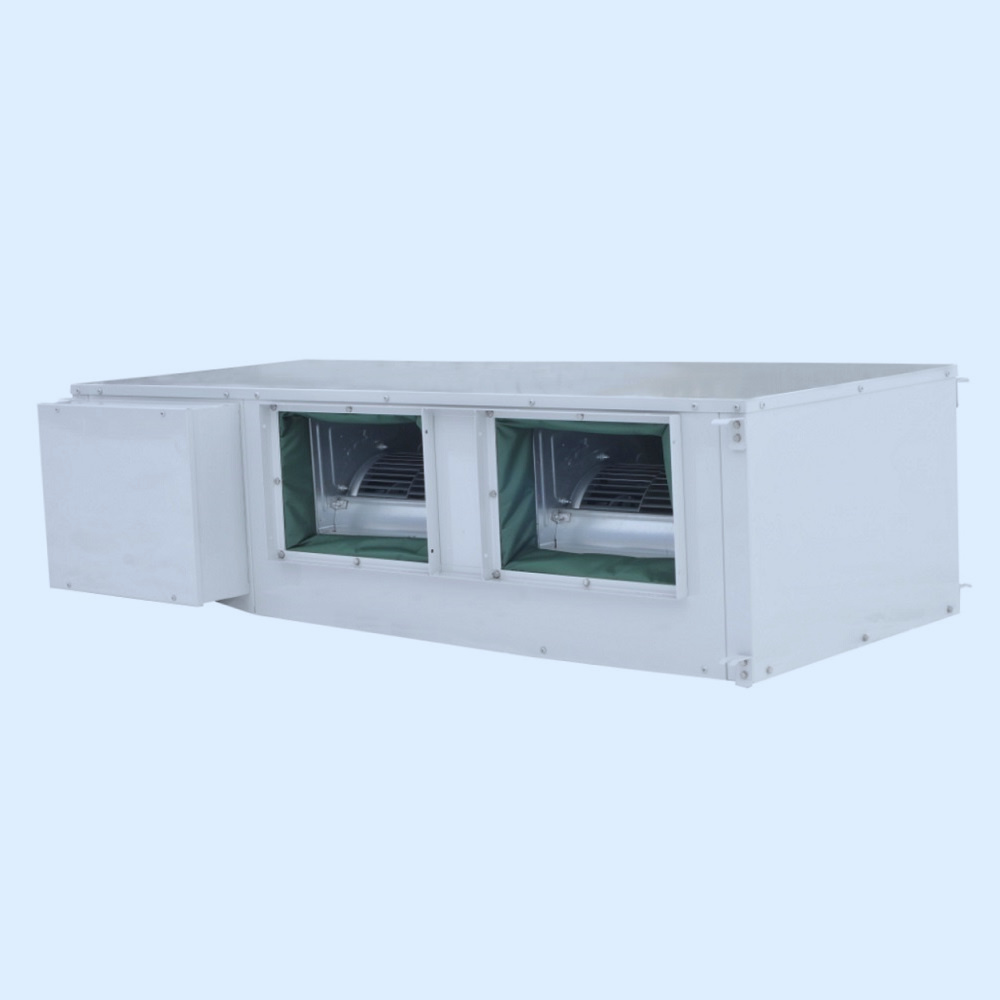

Air Cooled Water Chiller & Heat Pump With Screw Compressor

Sendo could provide customized solutions for your application:

•Exact capacity can be ordered based on projects requirement

•Cooling only or heat pump

•Refrigerant is optional, R22, R407c or R134a

•Heat recovery / Free cooling

•Low ambient temperature cooling

•Process cooling, customized inlet/outlet water temperature

•Build-in hydronic module can be configured as required

•Be able to connect to BAS Building Automation System

Features

Modular design

Each microcomputer controller of the unit reserves the interface for connecting the combined control module. Networking control between units can be implemented by cable connection and simple master-slave settings. Maximum 8 chillers can be controlled in a combined system, which means that the capacity can be easily expanded to meet various air-conditioning requirements. In a combination system, if one module failed, other modules can be back-up for continuing operation.

Reliable operation

All parts and control components of the unit are provided by world-famous reliable suppliers to make the unit energy saving & reliability, such as Bitzer compressor & Danfoss EXV and Schneider electric etc. The unit uses the advanced electronic expansion valve option, which ensures excellent performance both under full load or partial load and higher control accuracy.

Each unit will be tested during the production & before delivery to verify its operational reliability and to ensure a smooth startup. The performance, reliability and structure of the unit have been optimized by the long-term simulation tests under various changing conditions and extreme conditions.

Easy and fast installation

The water pipe of the water-side heat exchanger has been equipped with the water flow switch, which saves the on-site installation time. Water inlet and outlet pipes are equipped with flange connection, which makes the on-site installation easier.

The unit comes with the startup cabinet & control cabinet and has been filled with refrigerant & refrigeration oil before delivery. The unit can be placed in service after being connected with power supply and water supply.

The built-in hydronic module is optional. This module integrates all necessary hydronic components such as the water pump, filter, expansion tank, flow switch, safety valve, pressure gauge and drainage valve etc.

Components

High efficiency screw compressor, Bitzer & Hanbell & Fusheng brand screw compressor is optional.

High efficiency heat exchanger

Condenser adopts the copper tube & hydrophilic aluminium fin coil type structure, the appearance is V-shape. This design increase the heat exchange area, reduce the temp. differences, thus increase the heat exchange efficiency by 20%. Water side heat exchanger built with high efficiency shell & tube heat exchanger, factory insulated with flexible close cell material.

External rotor type axial fans, equipped with three phase direct drive motors, low noise 8 poles, protection level IP54, provided with a protective outlet grille.

Electrical box consist of: compressor contactor, fan motor contactor, compressor isolating switch, fan protection breaker, phase sequence relay and microprocessor with function display.

Assembly Line